What is RFID?

RFID stands for Radio Frequency Identification.

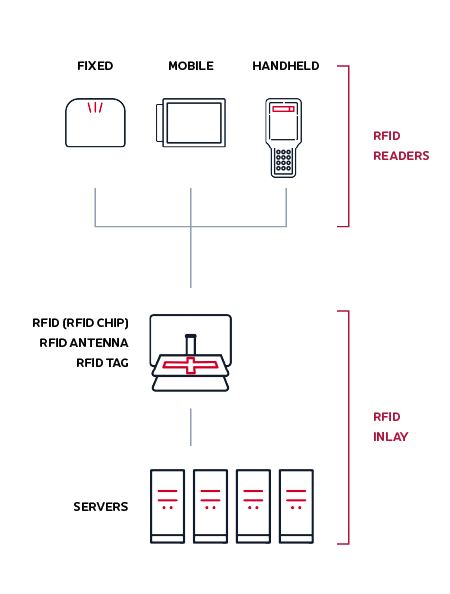

This technology uses Radio Signals to communicate a unique identity wirelessly, thanks to a microchip located in the RFID tag that contains the tag’s unique ID number (called Electronic Product Code or EPC).

Two different tags will never have the same ID number.

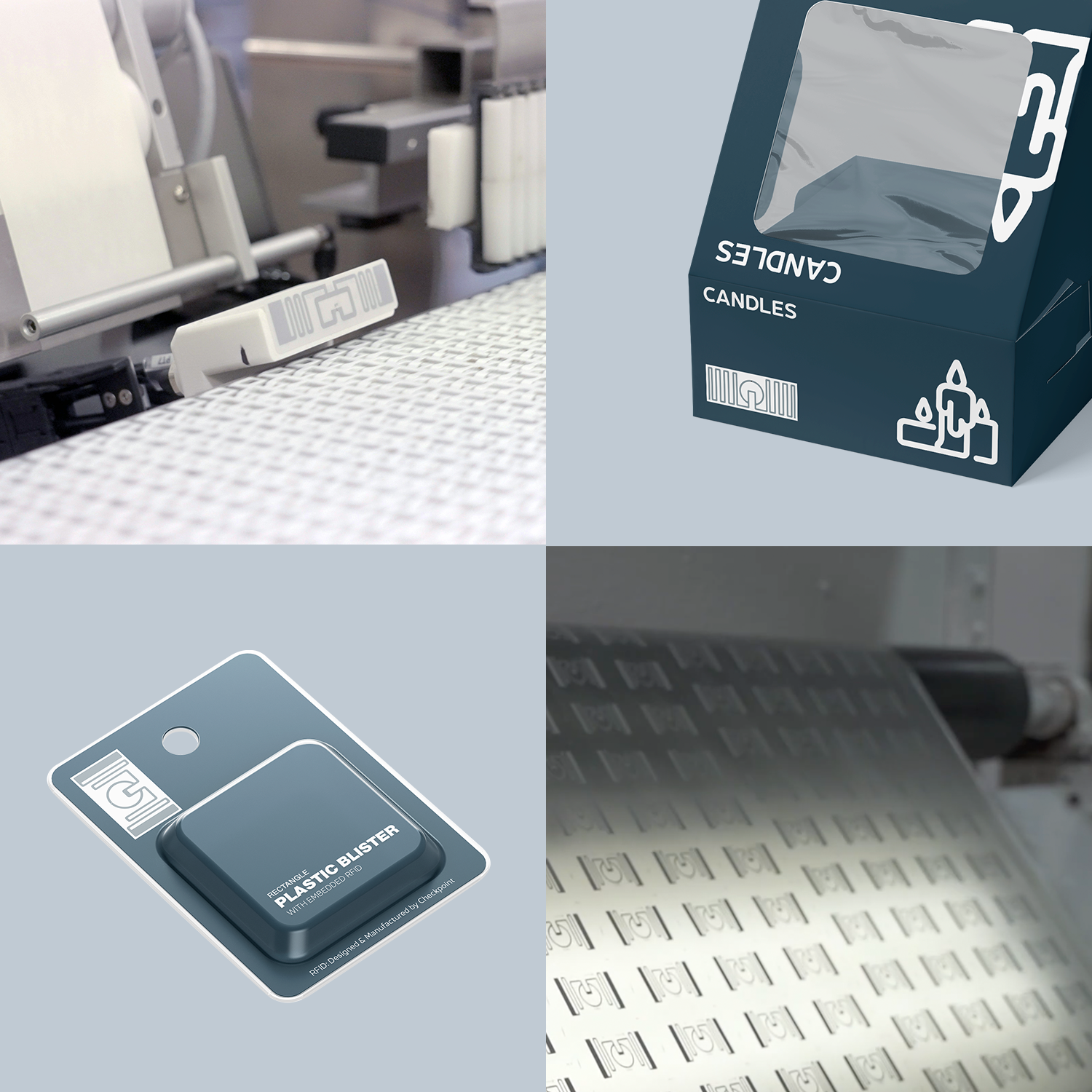

Radio Frequency Identification (RFID) technology ensures that each product SKU is unique and traceable throughout the supply chain, dramatically improving stock accuracy and data management.

The RFID solution for Walmart is being implemented with the aim of improving inventory accuracy and getting traceability of their goods at item level from source to shop at almost real-time.